A-Cat One-Off Custom Build: Q&A with John Lindhal & Larry Woods

In 2012 I published in csn an article on the LR4 one-off by the Lindhals. Currently I'm looking to build a one-off myself, and contacted John Lindhal to know more about his building process. He included a good friend in the loop also using the same one-off frame bed system, Larry Woods. Together they are building state of the Art one-off A-Cats.

The As have been always a Class of custom builts, in recent years new production series builders have contribute to the Class growth. But being able to set up your own boat and race with it, as Matt Strubble winning the 2013 NAs with his own boat or Jeremy Herring has done this year to grab a 3rd overall in the North Americans, it is a huge asset not many competitive dinghy/small cat classes can pair.

Beyond the build method & selected design , and from my previous experience in the F18, for a sailor there are not much better feelings in this world than building and sailing your own boat.

John & Larry gave us some interesting data on one-off frame bed process for those interested in giving a try. I'm working on cad A design also to be distributed (more on that later) , but the process I'm intending to use is the same being described in this Q&A

Complete LR5 build process at http://lindahlcompositedesign.weebly.com/lr5-build.html

LR4 build process at http://lindahlcompositedesign.weebly.com/lr4-build.html

Lindhal built Richard Roake's designed L Rudders at http://lindahlcompositedesign.weebly.com/new-rudders.html

---------

How long have you been building one-off custom A cats?

John Lindhal: 39 years

Larry Woods: Started off building a Farrier Tri several years ago and the go into A cats and built 2 boats in 2013

- Who is the responsible of the LR designs?

JL: Richard Roake in New Zealand

- How many you have built? Current version?

JL: 1- LR1, 3-LR2, 1-LR3, !-LR4, 2-LR5. Prior to the LR series I did

my own design starting with a Cal Fuller Catnip. LR6 is on the drawing board.

Larry Woods: 2 so far, plus lots of different rudders and daggerboards. Currently building Z boards for my own boat and a couple other guys.

- Are you building for others? The frame jig can be used for several hulls using your system.

JL: The frame jig makes home building easy and the frames can be used for several boats or easily stored.

LW: Mostly just building for me with a little for others to help find my own projects.

- You are using foam/corecell cores but cut in strips, excellent system for many without much building experience. I've built some frame/wooden strip models and the brushed & sanding is critical for a smooth final shape. With foam is less effort but you can easily sand off extra material.

So it is a more delicated process right? Which corecell density being used? JL: I am now using Corecell M-80, 3/8" thick.

Larry Woods: I bult the trimaran the same way as the A cats back in 2001-2005 Using 3/8 corecell and carbon skins. I like working with the corecell more that with wood. Just have to get use to the pressures applied while faring the foam.

I little more delicate, but much faster

- There are still some production As using foam cores instead of nomex, on experience with new As here in Arg is that they are quite fragile to punctures and can suck water easily.

Which other benefits (if any) of using corecell? Any structural drawback on using strips? JL: I like the idea of having more surface area to glue the carbon to, and the frame method won't work with honeycomb.

Larry Woods: No real drawbacks to using strips vs larger sheets since you glue each strip and the clue is generally stronger that the foam. Corecell is easier to work with wet layup where as with nomex wet lay up is more difficult to get even fillets around each honeycomb. Nomex is stiffer and a little lighter. but realistically the longest unsupported section of the hull is about 6 to 7' So in my opinion, not enough hull flex to worry about. The water issues are not a problem with the closed cell nature of the corecell.

- Recommend dyynicell/Corecell thickness and which outer / inner carbon laminates used?

JL: 3/8" foam with 5.8 oz IM carbon skins, laid on the bias on the inside and 0-90 on the outside. Proset Epoxy resin.

LW: 3/8" 4 or 5 lb density

- Filament winding beams can simplify the process of a custom built platform in a great degree. Are you using filament winding beams or moulded ones? JL: Filament wound from Forte.

Larry Woods: no, I bought my beams last time around, but I think I would build my own on the next go around. I will build a female mold and use an inflatable mandrel to make my own beams in the future. The right amount of uni-directional carbon and some woven sleeve materials will be fine. Putting a curve into the beam and then bending the ends down and burring them into bulkheads in the hull really stiffens up the beams and the entire platform.

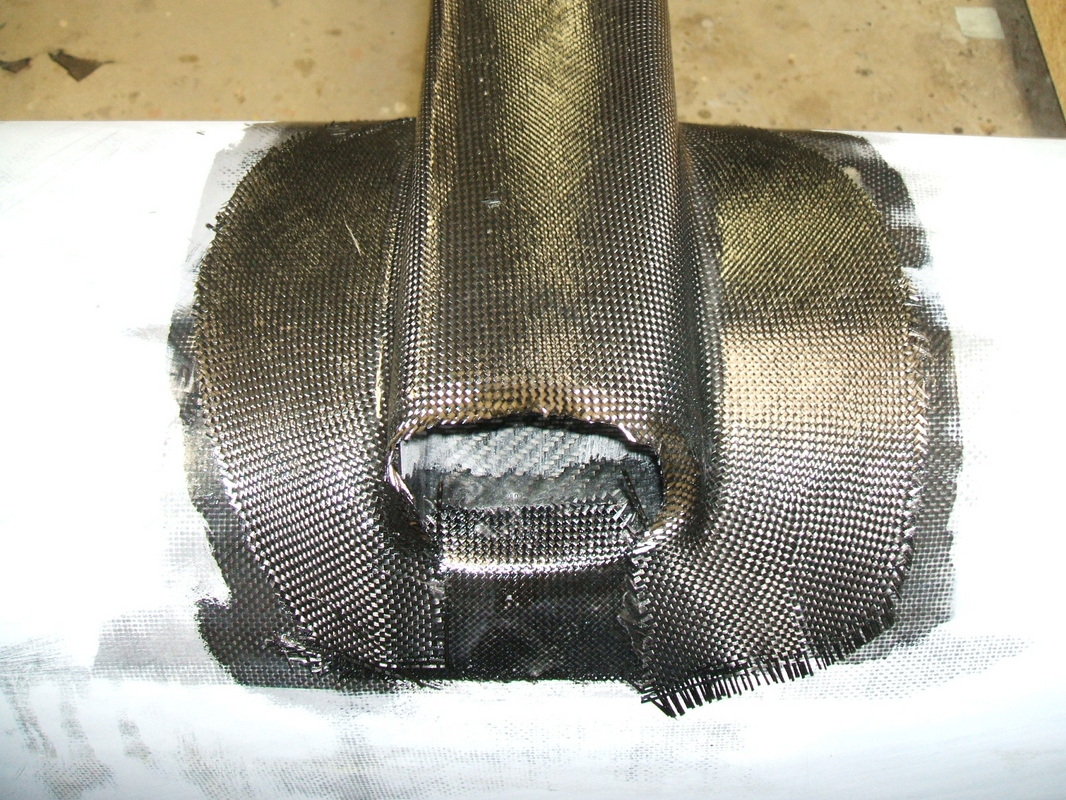

- You are relying on an outer laminate extra for fix beams (Scheurer use only surface bonding system) How stiff the platforms ends with the outer deck laminate bonding?

JL: I wrap under the beam onto the hull as well as over the beam to the hull. Stiffest boat out there.

LW: My platform is very stiff, very comparable to the most popular designs out there now. Rapping uni around the attachment points and down the sides of the hull helps stiffen and spread the twisting forces. next time will build the curved beams as mentioned and attach to bulkheads.

- Which are roughly the material costs a home builder needs to budget?

JL: $6,000. for the platform.

LW: Platform will cost you 8 to 10000

- The reversible frame system sounds a great idea. It is cost worth it or in the end is better to ivest in two separate beds? JL: Saves space and cost when you do reverse.

LW: it is a very cheap and great way to build. and when you are done, just take them apart and they store very easily. building two sets, would be ok if building several boats at the same time even with me building two boats, it was fine with one, just pulled 4 halves first and then flipped the forms around.

- Aprox Building hand labor hours?

JL: 400 hours.

LW: not sure. 6 months to build 2 boats, boards rudders, rudder heads, tramps and boom. and rig the entire boats.

- If you provide the service, which is aprox cost of a finished painted platform ex foils ?

JL: Around $16.000.

- I've seen your L rudders by Richard Roake, are you guys foiling already in your LRs? How about daggers, which ones are you using?JL: Roake has Z-foils designed, which I would use. No foiling yet on the LR5

LW: My design is not a Roake boat, but my own hybrid of several boats. Love RR boats, owned one in the past, I just enjoy building too much to not build my own. I will be foiling in March

- The LR5 looks really good, how about the sailing?

JL: Excellent

LW: The LR5 is an awesome boat. does everything well. When RR gets his foil package built I have no doubt it will be a fast combination.

- Mast and sails you guys are using?

JL: Fiberfoam bendy with a North sail by Henry Bossett.

Larry Woods: My brother and I use FF bendy masts and Glaser and Landi sails. Love the masts, and I like both sails as well.

- Any other additional comment

JL: Use Gorilla glue to bond the foam strips together.

LW:They are not cheap to build. but rewarding. having my own CNC machine helps a ton as any design changes are make quickly into new molds.